What to Know: Placards and Labels for Dangerous Goods Transport

Transporting dangerous goods requires more than just careful handling; it demands a comprehensive understanding of the labels and placards that communicate potential hazards. These markers are not just symbols; they’re vital communications tools that ensure the safety of everyone involved in the transport process, from handlers to emergency responders. This post dives into the significance of these safety measures, exploring why they’re crucial for safety and compliance in the logistics industry.

Importance of Proper Labeling and Placarding for Safety and Compliance

“Correct labeling and placarding are your first lines of defense in the event of an incident,” states Michael S. Whittaker, a safety compliance expert. “They provide critical information at a glance, which can be lifesaving in emergency situations.” Indeed, proper labeling isn’t just a regulatory requirement; it’s a pivotal practice that minimizes risks, ensuring that dangerous goods are transported safely and responsibly. Here are some key reasons why proper labeling and placarding are crucial for safety and compliance:

- Identification of hazards: Labels and placards provide quick identification of the type of hazardous material being transported, along with any potential risks associated with it. This allows handlers to take necessary precautions when handling or responding to an emergency.

- Prevention of accidents: By clearly communicating the potential hazards of dangerous goods, labels and placards help prevent accidents or incidents during transportation. They serve as visual reminders to handle these materials with care.

- Regulatory compliance: Proper labeling and placarding are mandatory requirements set by regulatory bodies such as Transport Canada, the Department of Transportation (DOT) in the United States, and the International Maritime Organization (IMO) internationally. Non-compliance can result in penalties, fines, and even legal consequences.

- Protection of emergency responders: In case of an accident or spill during transport, emergency responders need to be able to quickly identify the hazardous materials involved. Labels and placards provide crucial information for their safety and enable them to take appropriate measures.

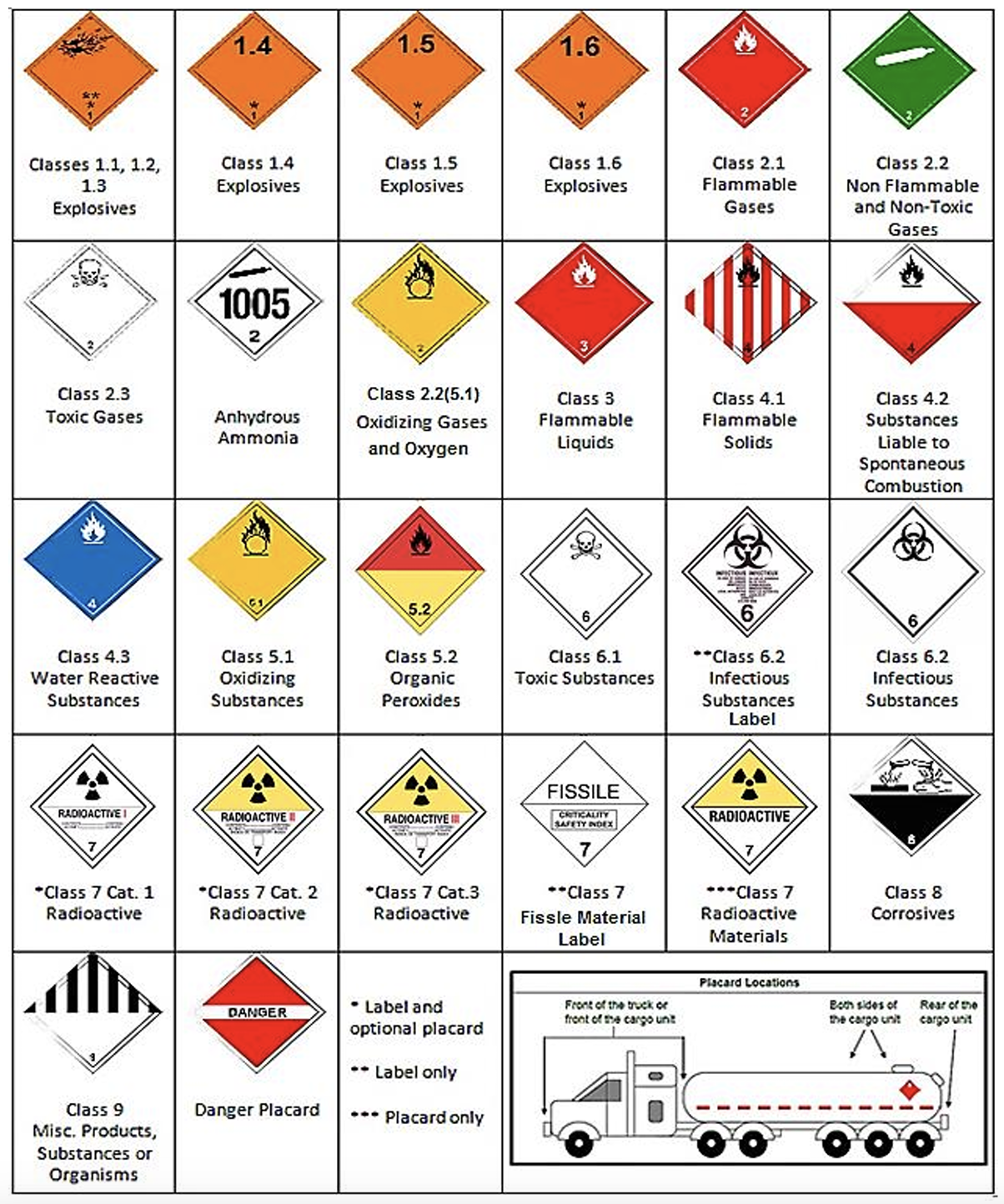

Types of Placards and Labels Used for Dangerous Goods Transport

Now that we understand the importance of labeling and placarding in dangerous goods transport, let’s take a closer look at the different types of markers used for this purpose:

- Class labels: Dangerous goods are classified into nine classes based on their properties. Class labels are used to identify which class a particular material belongs to, such as explosives, flammable liquids, corrosive substances, etc.

- UN number labels: All dangerous goods are assigned a unique United Nations (UN) number, which is used to identify them during transport. UN number labels include the material’s proper shipping name, hazard class, and ID number.

- Placards: Placards are larger versions of class labels that are affixed on all sides of the vehicle or container carrying hazardous materials. They provide a visual warning to emergency responders and the general public of the potential hazards within.

- Handling labels: These labels are used to indicate how dangerous goods should be handled during transport, such as “flammable,” “keep upright,” or “do not stack.” They provide critical information for handlers to ensure safe transportation.

Tips for Proper Labeling and Placarding

To ensure proper labeling and placarding for dangerous goods transport, here are some essential tips to keep in mind:

Stay updated with regulations: Regulatory requirements for labeling and placarding can change over time. It is crucial to stay informed about any updates or changes to ensure compliance.

Use the correct labels and placards: Different materials have different hazards and require specific labels and placards. It’s important to use the correct ones for the materials being transported.

Ensure proper placement: Labels and placards should be placed on all sides of the vehicle or container, so they are visible from all angles. Improper placement can lead to confusion or delay in emergency situations.

Keep labels and placards legible: Labels and placards should be clearly visible, legible, and free from any damage that could obscure the information. If a label or placard becomes illegible, it must be replaced immediately.

Train personnel: All personnel involved in handling dangerous goods should receive proper training on labeling and placarding requirements to ensure they can handle materials safely and comply with regulations.

Adopt technology: In recent years, innovative technologies have gained popularity. These sophisticated software solutions and tools are crafted to assist truck drivers in safely transporting hazardous materials. We recommend Nutech TDG, a specially developed app that guides the placarding of trailers transporting dangerous goods in compliance with Canadian regulations.

Implementing industry best practices for placarding and labeling involves regular training for all personnel involved in the transport of dangerous goods, from drivers to packaging specialists. It also means conducting rigorous checks to ensure all labels are accurate and compliant with the latest regulations. “Consistency in applying these practices can significantly reduce the risk of non-compliance and accidents,” O’Connell adds.

Understanding the Different Classes of Dangerous Goods and Their Corresponding Placards

Dangerous goods are categorized into nine classes based on their nature and the specific hazards they present. Each class has its unique symbols, colours, and numbers, designed to be universally understandable:

Class 1: Explosives – This class are explosives or any devices or chemicals that are designed to explode or combust. Examples include ammunition, fireworks, flares, primers, ignitors and air bag inflators.

Class 2: Gases – This class includes compressed, liquefied, or dissolved gases that pose a risk of fire or explosion. Examples include propane, helium, and carbon dioxide.

Class 3: Flammable Liquids – This class includes substances that are liquid at room temperature and can ignite easily when exposed to heat, sparks, or flames due to their low flash points (60 degrees Celsius/140 degrees Fahrenheit). Common examples include gasoline, alcohol, paint thinners, and certain types of paint.

Class 4: Flammable Solids – This class includes solids that can ignite spontaneously when exposed to heat, water, or friction. Examples include matches, fireworks, certain types of metals, and sulphur.

Class 5: Oxidizing Substances – This class includes materials that can cause spontaneous combustion or increase the intensity of a fire. They can also cause dangerous reactions with other substances. Examples include hydrogen peroxide and potassium permanganate.

Class 6: Toxic Substances – This class includes materials that are poisonous or capable of causing severe health hazards. These materials can cause harm or death when exposed to humans, animals, or the environment. Examples include pesticides, cyanide, arsenic, and biological materials such as viruses or bacteria.

Class 7: Radioactive Materials – This class includes materials that emit ionizing radiation and can be harmful to human health, living beings, organic matter, and the environment. They require specialized handling during transportation. Examples include uranium, plutonium, and medical isotopes.

Class 8: Corrosive Substances – This class includes materials that can cause severe damage to living tissue or other materials they come in contact with, including living tissue. Examples include sulphuric acid, lye, strong acids and bases.

Class 9: Miscellaneous Dangerous Goods – This class includes materials that do not fit into any of the other classes but still pose a risk during transportation. Examples include lithium batteries, dry ice, and asbestos.

By understanding the different classes of dangerous goods and their corresponding placards, personnel can quickly identify the hazards involved in transporting materials and take appropriate safety measures. This knowledge is crucial for ensuring the safe handling, storage, and transport of dangerous goods.

Dr. Elizabeth Dawson, a hazardous material specialist, emphasizes, “Each label and placard is meticulously designed to convey risks. From the flammability of liquids in Class 3 to the biohazards in Class 6, clear communication can significantly mitigate accidents.”

Learn more about the different classes of dangerous goods

Future Trends in Placarding and Labeling Technology

Emerging technologies such as QR codes and RFID tags offer exciting possibilities for the future of labeling and placarding. These innovations promise to make information more accessible and dynamic, potentially transforming how risks are communicated in the transport of dangerous goods. For instance, QR codes on labels can provide real-time tracking of shipments and instant access to safety data sheets for emergency responders.

Nutech TMS recently launched a mobile application, Nutech TDG, previously mentioned, designed to assist truck drivers in correctly placarding trucks according to Canadian regulations. This innovative tool enables fleet managers, compliance officers, and safety managers to guarantee adherence to safety standards when transporting hazardous materials. It enhances efficiency, minimizes driver confusion, and ensures the secure handling of dangerous goods.

Conclusion

The transport of dangerous goods is a critical yet risky aspect of the logistics industry. By understanding and implementing proper labeling and placarding practices, companies can ensure the safety of their operations and compliance with global standards.

“We are at a pivotal moment where adopting best practices isn’t just about compliance; it’s about commitment to safety,” concludes Whittaker. In this spirit, logistics professionals, compliance managers, and all stakeholders are encouraged to continually seek knowledge, share insights, and adopt the latest safety measures in dangerous goods transport.

Remember, when it comes to dangerous goods transport, the stakes are high, and the margin for error is slim. By prioritizing safety and compliance through accurate placarding and labeling, we can protect lives, assets, and the environment.

If you’re a logistics professional looking to stay ahead in the industry, follow us on LinkedIn, Facebook, or Instagram. Together, we can create a safer and more compliant transport of dangerous goods.